For more info on this product, check out the following pages:

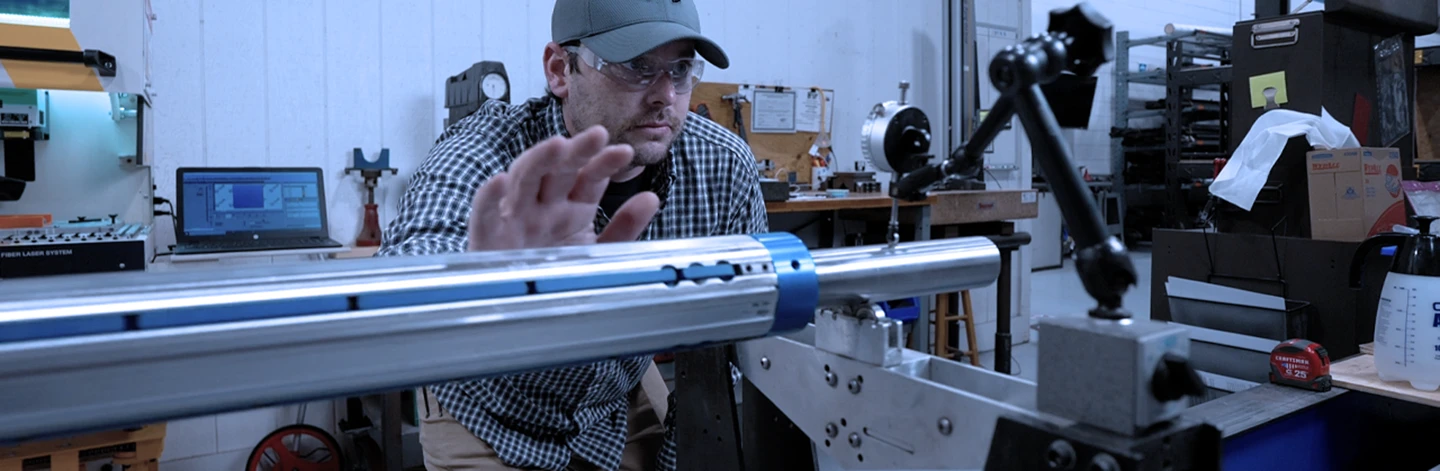

Nip Feed Station used with Die Cutting Machine

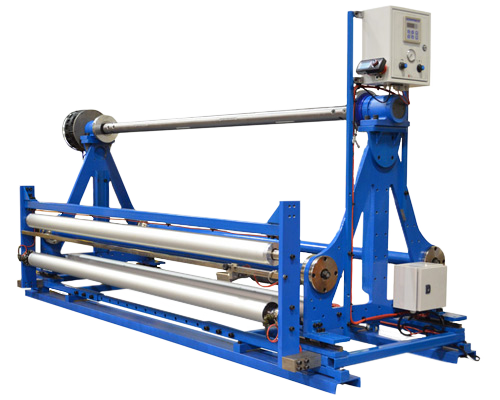

Producer of Plastic Sheets Upgrades Production Line with Retrofit Double Unwind Stand

Producer of Plastic Netting Upgrades Unwind Stands with Simple Retrofit System

Producer of Laminates and Performance Films Increases Capacity and Cut Quality with Retrofit Section