Jan 01, 2016

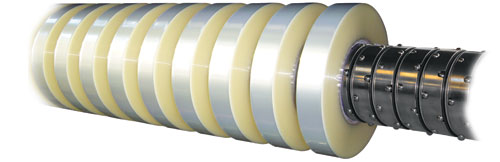

Double E Company’s new differential rewind shaft (DRS) delivers consistently wound rolls even when material thickness varies.

Lighter and stronger 6-inch

Web material often has differences in thickness and/or coating thickness across its width. These variations create a need for a shaft that acts like a clutch to all the rolls so that they each wind with the same torque all the way across the web. Double E is pleased to offer a shaft that creates uniform rolls, even when thickness variations are extreme.

Double E’s differential rewind shaft works like a “shaft within a shaft”. Winding cores are mechanically locked onto one or multiple friction rings, depending on core width. When the outer race is rotated against the inner race of the friction ring, the expanding balls ride up cam ramps to center and grip the core. These friction rings then consistently slip like a clutch around a central shaft, which runs at an overspeed RPM. Similar to a strip shaft, this central shaft contains air bladders and friction strips running along the shaft. Winding torque to the friction rings (and consequently to the cores and rolls) is controlled by adjusting the air pressure in the bladders. As the bladders expand, they press the friction strips out to exert force on the inner surface of the friction rings. Generally, as rolls build, air pressure is increased to deliver the proper winding torque. Because the web material may have variations within it, some rolls will slip more than others to creat uniformly wound rolls.

For more information, please contact the Double E Company. Tel: 508-588-8099 info@ee-co.com https://ee-co.com/products/differential-rewinding-core-shafts

Thank you for your interest in Double E. We'll be following up soon!