The life of a converting machine is not always an easy one. Between the high-speed rotation of the rollers and pressure on the belts, webs, and other parts, converting equipment can wear down over time.

Catching defective or worn-down converting machinery can save you a lot of money in both ongoing maintenance costs and downtime. However, it’s not always clear whether it’s best to replace or repair equipment. We're here to walk you through when to repair vs. replace your converting equipment.

Signs that Your Converting Equipment Needs a Repair

There are some clear indications that heavy machinery, such as converting machines, is malfunctioning. The telltale signs that it's time to invest in repair services include the following:

- Lower output quality

- Warning lights

- Machine leaks

- Excessive or irregular vibrations

- Unusual noises while an operator is using the machine

Once again, failing equipment can lead to downtime. Machines that need regular maintenance can affect customer satisfaction, so it’s best to fully repair issues when spotted instead of limping along with worn equipment.

Your valued operators might also feel discontent around working with machines that don't perform well. You should hire a knowledgeable technician to resolve the issue when you recognize that your machinery doesn't have the best output.

Signs That Your Converting Equipment Needs a Replacement

Sometime repairs aren’t enough to restore your production line. While repairs are a good for an initial attempt, It's best to replace your converting machine(s) if:

- Your equipment is over twenty years old

- Your machinery has had several repair services performed in the last few months or years

- Your device's output quality and efficiency never seem optimal.

- Repair costs are 50% or more than replacement costs

- Replacement parts are not available or have significant lead times.

- The machine is abnormally hot due to overheating.

In many cases, it's hard to tell when your converting machine has exceeded its lifespan. In this scenario, the best thing to do is contact a credible repair technician to assess the issue. A well-informed engineer can tell you if your machine is worth salvaging or if you should invest in new equipment.

How to Prevent Converting Equipment from Being Damaged

One way to avoid the question of repair vs replace is to take measures to maintain the durability and efficiency of your converting equipment. There are several steps that you can take each day to keep your equipment running smoothly, such as the following:

- Clean your converting equipment by vacuuming out any accumulated dust or particles and using a brush to carefully remove any stubborn dust particles

- Ensure that your machines are clean after each use by wiping down the devices with a cloth and using tweezers, as necessary, to remove debris

- Check the machine's oil levels, belts, pulleys, air filters, electrical connections, bearings, hydraulic fluid levels, and checking hydraulic hoses for leaks or damage

- Run your converting machine at the correct speeds

How Long Should a Converting Machine Last?

High-quality converting equipment should withstand years of extensive use in various industrial manufacturing settings. However, even the most efficient converting machines degrade over time, inevitably reaching the end of their lifespan.

Ensuring that your equipment lasts as long as possible involves routine maintenance. On average, a converting machine lasts between 15-20 years. You should reach out to your converting equipment provider to develop a maintenance schedule to keep your machinery in top condition for a long time.

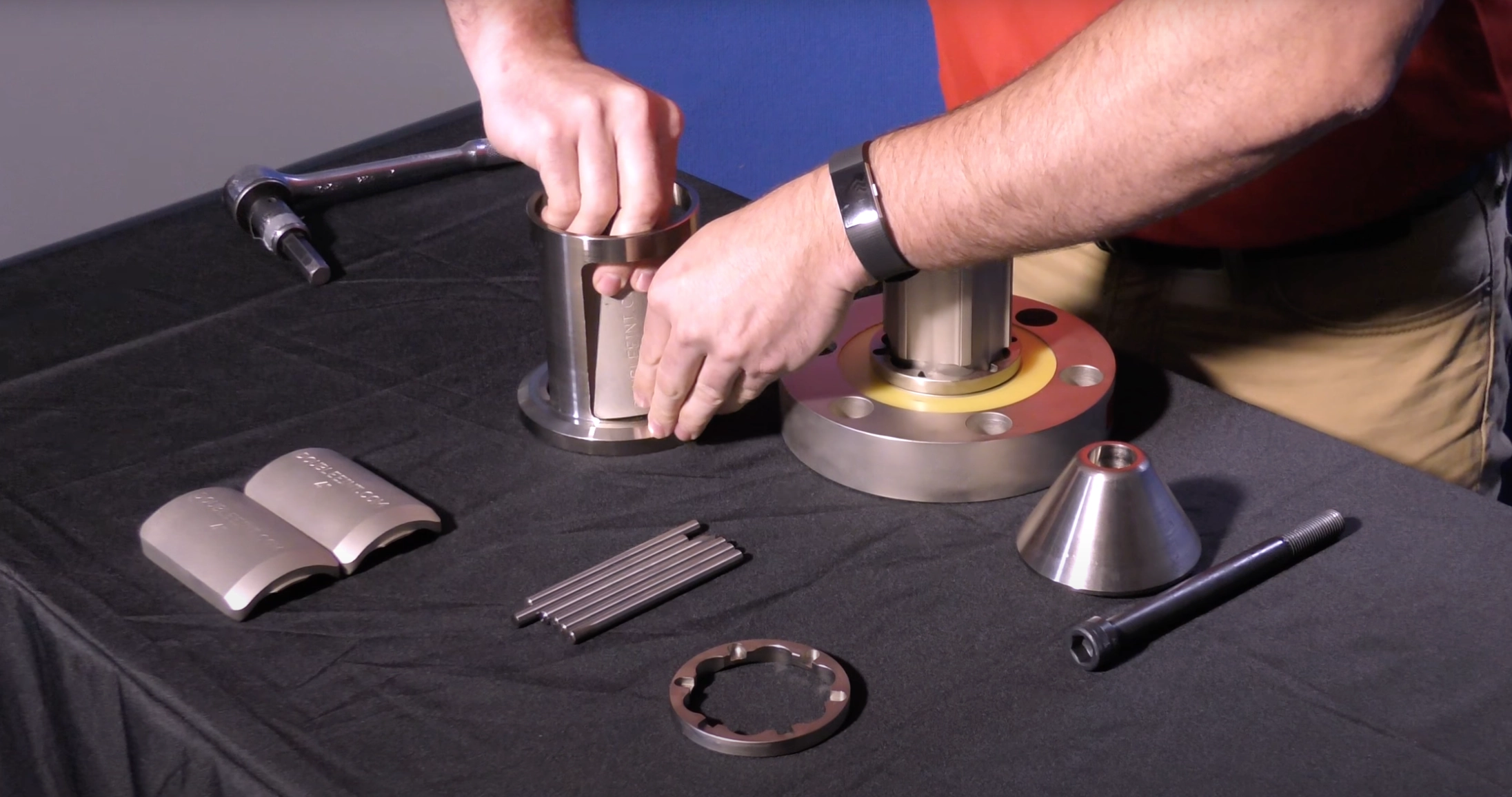

Double E Provides High-Quality Replacement Parts for the Converting Industry

Whether you want to expand your production floor or extend the life of your current machines, the right converting equipment makes a major difference. Our cutting-edge core chucks, shafts, cutters, brakes, rollers, and parts for slitting machines are lightweight and efficient and keep OSHA's safety standards at the forefront. We also manufacture roll stands to make your manufacturing processes or even more streamlined.

We look forward to working with you to find customized web converting solutions. Check out our success stories and contact the Double E team today to learn more about how our parts can maximize your production.