For more info on this product, check out the following pages:

Double E Group Partners with Dotec for Enhanced Handling in Americas

Dotec Roll Handling Systems

High-performance pneumatic roll lifters for safe, ergonomic, and efficient material handling

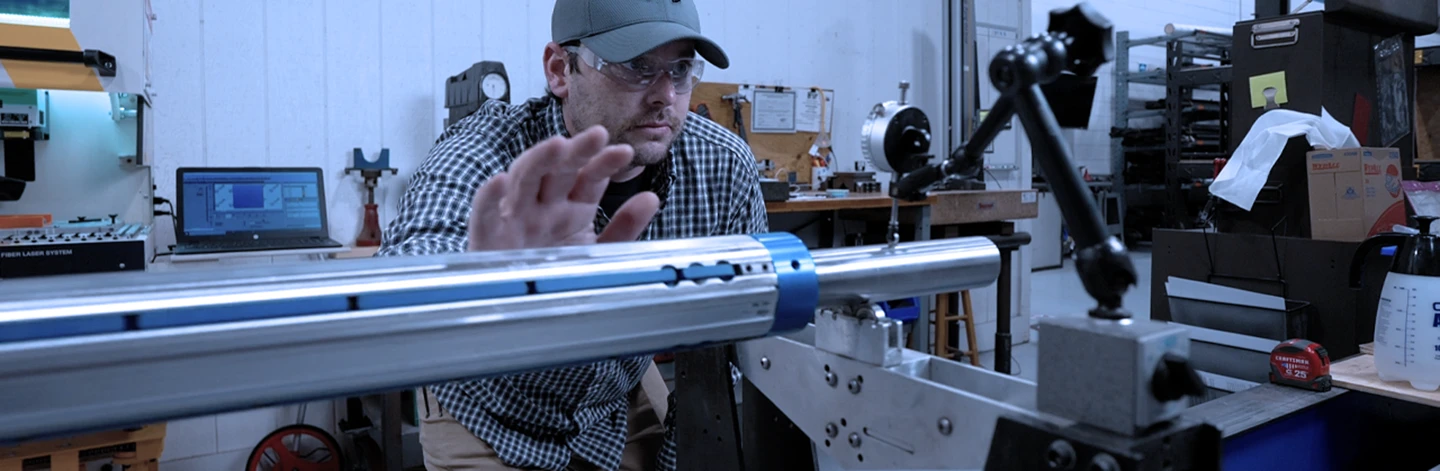

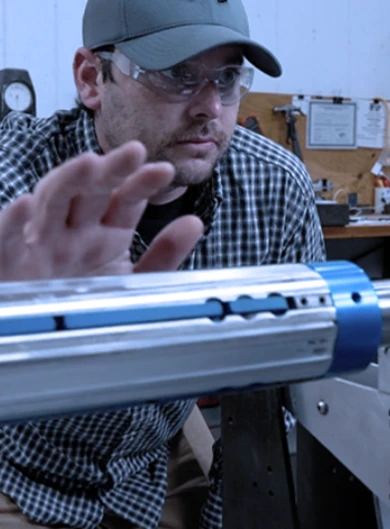

Dotec Roll Handling Systems are innovative, ergonomic lifting solutions specifically designed for safely lifting, turning, tilting and/or rotating rolls of paper, film, foil, textiles, and other flexible materials. Engineered with the operator in mind, these pneumatic-powered roll lifters are ideal for industries where speed, precision, and worker safety are paramount.

Dotec systems utilize a unique combination of compressed air technology and intuitive controls to allow a single operator to manage heavy roll loads with minimal physical effort. By integrating Dotec roll handlers into your production line, you can drastically, minimize the risk of injuries, optimize the flow of your operation, and reduce downtime through remote support.

Dotec's Friendly LiftAssist system is designed for ease of operation, speed, and ergonomics, all thanks to its unique design features.

The user-friendly design is all thanks to the central features of the LiftAssist:

Benefits:

Roll Handler Examples

| Model | Lifting Capacity |

|---|---|

| RH50 | 110 lbs (50 kg) |

| RH100 | 220 lbs (100 kg) |

| RH150 | 330 lbs (150 kg) |

| RH200 | 440 lbs (200 kg) |

| RH230 | 507 lbs (230 kg) |

| RH250 | 550 lbs (250 kg) |

| RH500 | 1100 lbs (500 kg) |

Product Features

Dotec Ergohandle

The central feature of the LiftAssit is the Dotec Ergohandle. The Ergohandle allows for intuitive control of the lifters with no more effort than a fingertip touch to control both direction and speed. The ergonomic handle glides freely up and down through the operator’s hands – no bending or stretching needed when lifting to high or low positions.

The Ergohandle also features proportional speed – the handlers move slowly with a light press and faster the further you press. Up and down movement of the handler is controlled by one set of handles while tilting/rotating and roll release is done with a second set of handles set behind the first. This configuration keeps operators able to keep their hands easily on the handler, comparable to steering a car, and operate the full capacities of the handler. Simple, intuitive controls also means the learning curve for operators is short. The handler must always obtain enough counter pressure in order to release a roll so products cannot accidentally be released during the lifting process – safety first!

Air-Balancer

The air-balancer makes the elastic vertical movements of the LiftAssit possible. The winding and unwinding of the system’s balancer cable. This also creates an air cushion to support the load when it is stopped and keep it balanced.

Additional Options

Infrastructure

To ensure smooth operation, The LiftAssist requires the correct infrastructure setup to allow for horizontal movement of the handler. Designed for a 24/7 production environment, the system’s high-speed performance along with ease of use and safety make the Dotec system a reliable choice for continuous operations. To make this all possible, the infrastructure is the backbone of the Dotec total system. Most common solutions are a rail system or jib crane – determined by area lay-out.

Rail systems and Gantries

Rail profiles provided a minimal rolling resistance of ≤1% of the load. With a strong but light profile made from aluminum, large spans and load capacities can be achieved. Gantry systems created seamless maneuvering across production layout and come equipped with Dotec’s top-quality, aluminum rails. Systems are custom based off required dimensions to suit your operation.

Jib crane

Where space or headroom is limited, a jib crane can be used. Perfect for short transfer process, jib cranes are designed for ergonomic, smooth movement while handling loads. Rotation can be locked to ensure safety and accommodate the needs of the process. The aluminum rail provides strength without sacrificing strength.

Over 40 Years of Ergonomic Innovation

With over four decades of engineering experience and thousands of installations worldwide, Dotec is a trusted partner for companies seeking reliable, ergonomic lifting solutions. They focus on operator comfort, production efficiency, and product safety.

Dotec also strives for perfections - with every installation, customers will receive instruction and training on their system. Dotec does not leave until your handler is in perfect working condition!

If you are looking to improve your roll handling process, contact us today to learn more about how we can customize a solution for your operational needs.

Which products are best for you?

Back to Top