PRODUCT FINDER

Which products are best for you?

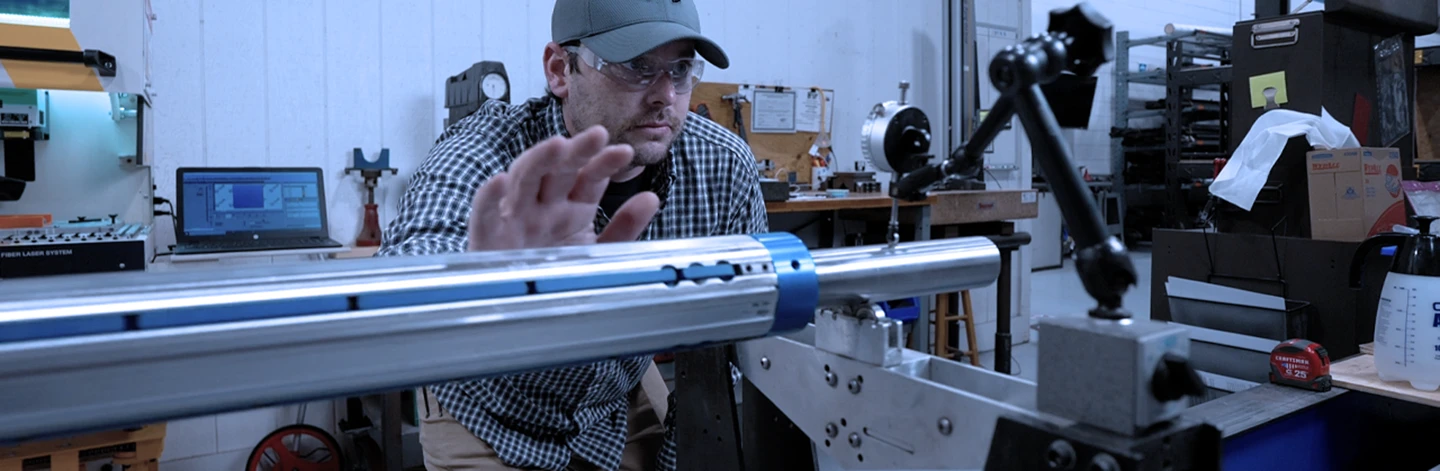

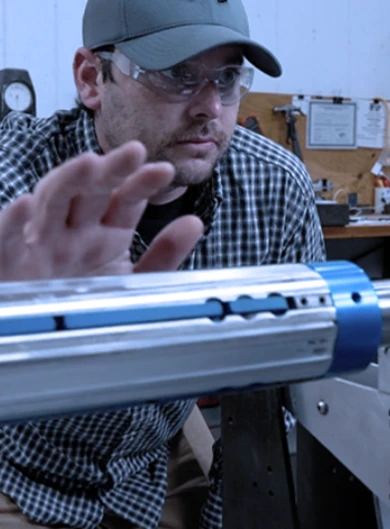

Spreader Rollers

In the converting industry, a spreader roller plays a critical role in ensuring consistent web handling and material quality throughout the production process. Designed to eliminate wrinkles, slack edges, and uneven tension, spreader rollers help maintain proper web alignment as materials move through coating, laminating, slitting, and rewinding operations. By evenly distributing the web across the machine width, a spreader roller improves downstream accuracy, reduces waste, and supports higher operating speeds without compromising product integrity.

Modern spreader roller designs are engineered to accommodate a wide range of substrates, including films, foils, papers, nonwovens, and textiles. Whether utilizing bowed rollers, expanding rollers, or specialty surface coverings, these components are essential for optimizing tension control and minimizing defects caused by creases or tracking issues. In high-performance converting lines, the correct selection and placement of a spreader roller can significantly enhance process stability, extend equipment life, and deliver consistent, repeatable results across demanding applications.

Spreader rollers spread thin plastic film and tissue wrinkle-free. They can have a rubber or silicon covering depending on the type of material to spread. The profile is shaped by helicoidal grooves from the center to the outside edges of the roller. The roller works flat and guarantees a perfect tension uniformity across the total surface. Its easy rotation guarantees smooth running of the material.

Which products are best for you?

Back to Top