PRODUCT FINDER

Which products are best for you?

Load Cells

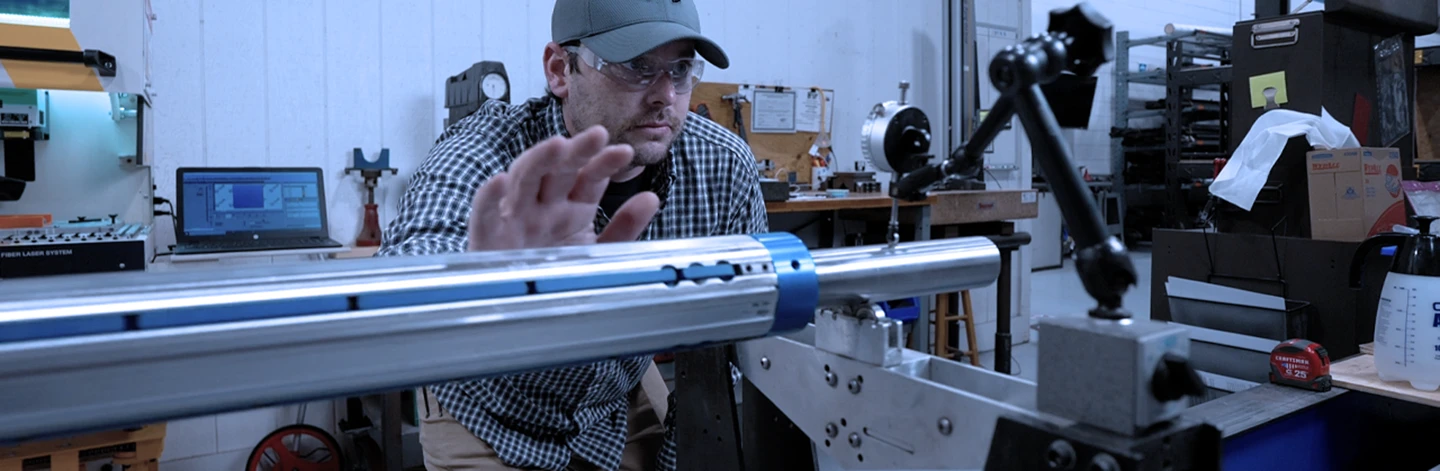

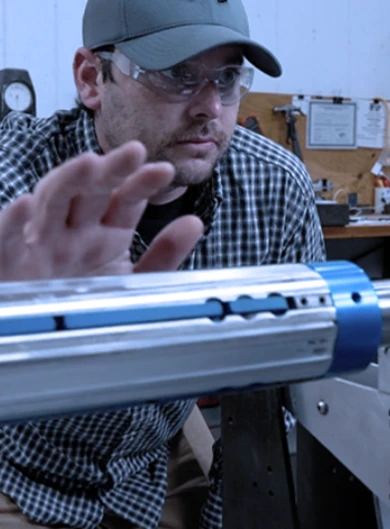

Double E Group load cells are designed using a full Wheatstone bridge strain gage mounted to a beam supporting the load cell bearing cup. Force from web tension is transmitted through an idler roller mounted to the load cells. A low voltage (mV level) signal is created proportional to the force which then needs to be amplified and used in a closed loop tension controller or tension readout device.

Load Cells

|  |

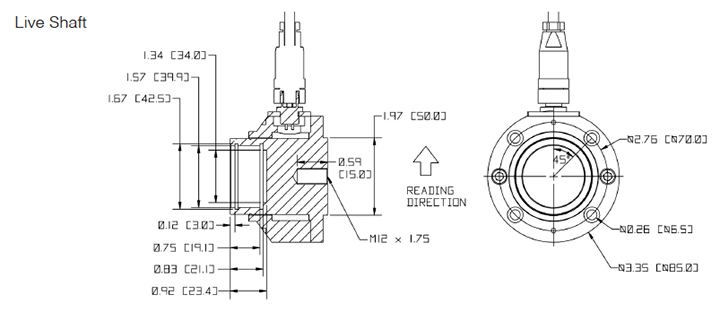

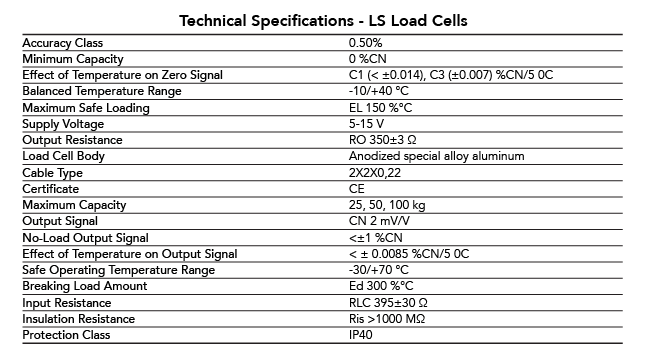

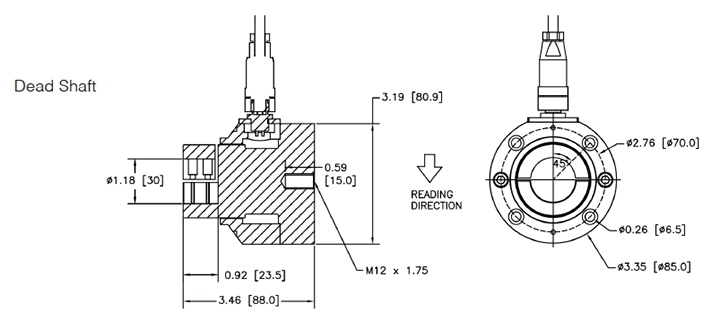

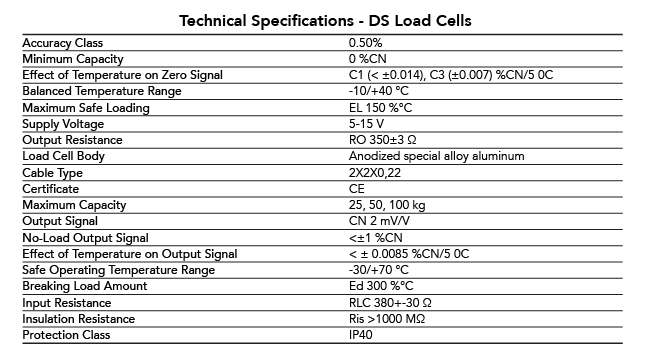

LS Model Load Cell | DS Model Load Cell |

LS are available in 15kg, 25kg, 50kg, 100kg

|

|

DS are available in 25kg, 50kg, 150kg

|

|

Which products are best for you?

Back to Top