PRODUCT FINDER

Which products are best for you?

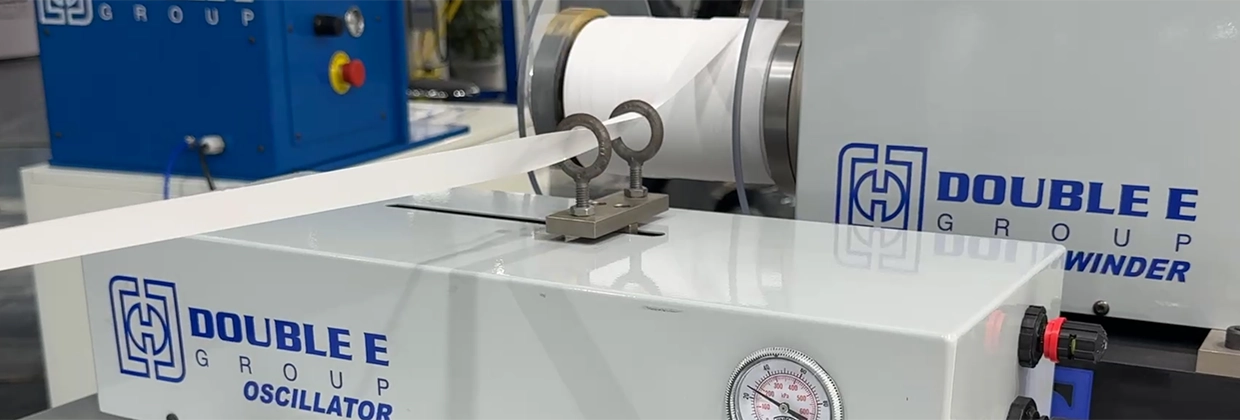

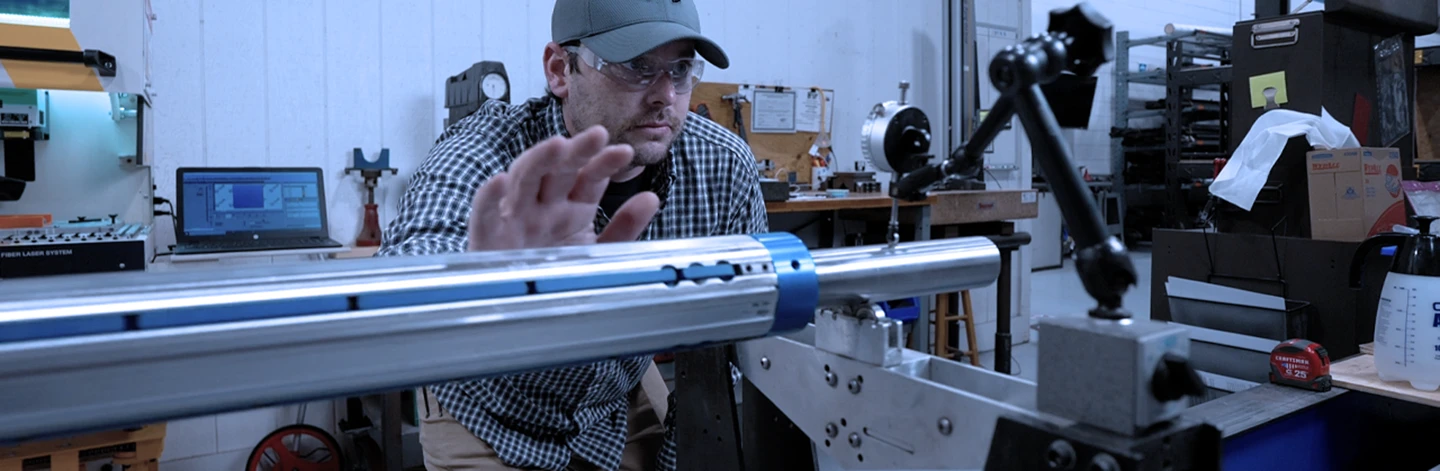

Double E Group’s Trim Removal Systems offer powerful, efficient solutions for collecting, winding, and conveying trim and matrix waste in paper, film, foil, and nonwoven converting productions. Our Pneumatic Trim Winders use compressed air for low-maintenance, motor-free winding. Double E Group Oscillators can be paired with our Pneumatic Trim Winder to ensure even roll builds and smooth trim distribution. Finally, the high-performance FOX TrimAway system uses a uniquely engineered venturi with a regenerative blower to create a powerful suction and discharge airstream for trim and matrix removal. This provides an energy-efficient, low maintenance operation that can be integrated quickly with existing equipment.

Which products are best for you?

Back to Top