PRODUCT FINDER

Which products are best for you?

FOX TrimAway Trim & Matrix removal

FOX TrimAway systems stand out for their unique and innovative use of regenerative blowers to create a powerful motivating airstream. The core of the system is FOX TrimAway's exclusive venturi which converts the blower’s motivating airflow into high-velocity suction at the intake and pressure at the discharge. The FOX system yields exceptional performance while still yielding significant energy savings compared to other trim removal systems. FOX TrimAway systems are also available in portable configurations, with or without our Trim-AX choppers. Our matrix removal solutions eliminate the need for matrix rewinding, streamlining your production process. FOX TrimAway systems provide a reliable, efficient solution that can be custom tailed to your specific needs.

FOX TrimAway systems deliver a clean, efficient, and versatile way to remove trim and matrix material for a wide range of converting operations. FOX TrimAway systems can be used to remove trim from paper, film, foil, textile, or nonwoven product as well as matrix materials. Designed to be installed quickly and easily, FOX TrimAway systems can be added to existing systems with limited downtime.

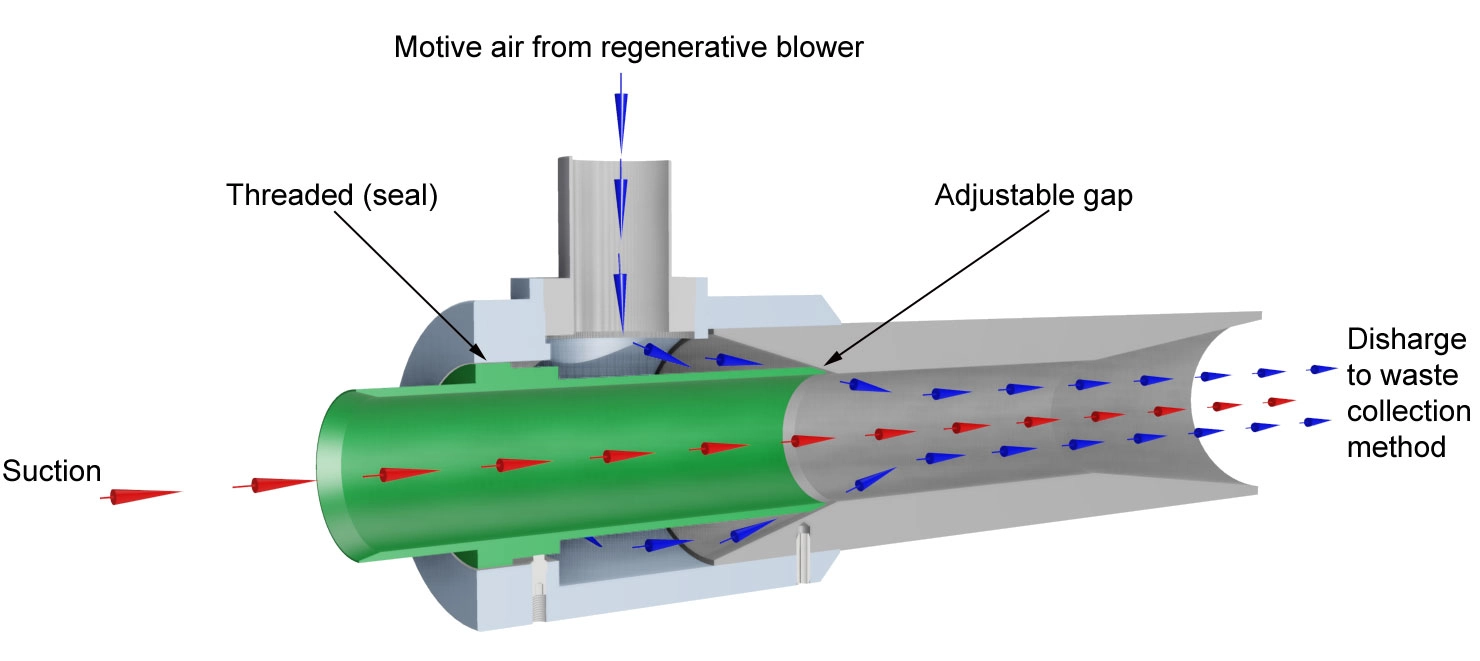

At the heart of every system, FOX TrimAway features an exclusive venturi which harnesses the blower’s airflow to generate powerful suction and discharge pressure for efficient trim removal without the need of moving parts or compressed air. This feature provides a more energy efficient system that is quieter and requires minimal maintenance. Productions benefit from long-term savings, cleaner, and safer environments for their operations.

FOX TrimAway systems use high-efficiency regenerative blowers to create a powerful motive airstream. This airflow is directed into the side of the venturi, where it makes a precise, high-speed turn through an adjustable gap in the venturi. This movement generates strong suction at the venturi intake. Each system is factory-tested and tuned for maximum performance, but the adjustable gap allows for suction adjustments to be made in the field as needed.

Waste is drawn into the venturi’s suction inlet and travels in a straight, unobstructed path. Because the trim never passes through moving parts or fan blades, it remains continuous and intact, eliminating the need for chopping and minimizing wear and maintenance. Waste can be conveyed over short or long distances with a powerful stream of air to a waste collection point.

FOX TrimAway Conveying Systems

The FOX TrimAway Conveying Systems use an exclusive venturi design and regenerative blower to create powerful suction and discharge airflow. This produces efficient, high-performance trim removal with significant energy savings over compressed-air systems. Systems can be customized with blower options from ½ to 20 horsepower and three venturi sizes to fit your production’s needs. Our customization options mean your system will be sized properly to provide ultimate performance and both initial and long-term operational cost savings.

Typical applications include:

FOX TrimAway Matrix Conveying Systems

In traditional operations, label and die-cut matrix waste is collected by rewinding it onto a scrap roll. This often leads to unnecessary downtime and inefficiency due to frequent roll changes. This also requires maintaining proper tension on larger rolls to reduce the risk of matrix breaks. The FOX TrimAway Matrix Conveying System eliminated the need to run wider and more costly webs along with the need to use cardboard cores in the rewinding process.

Typical Applications Include:

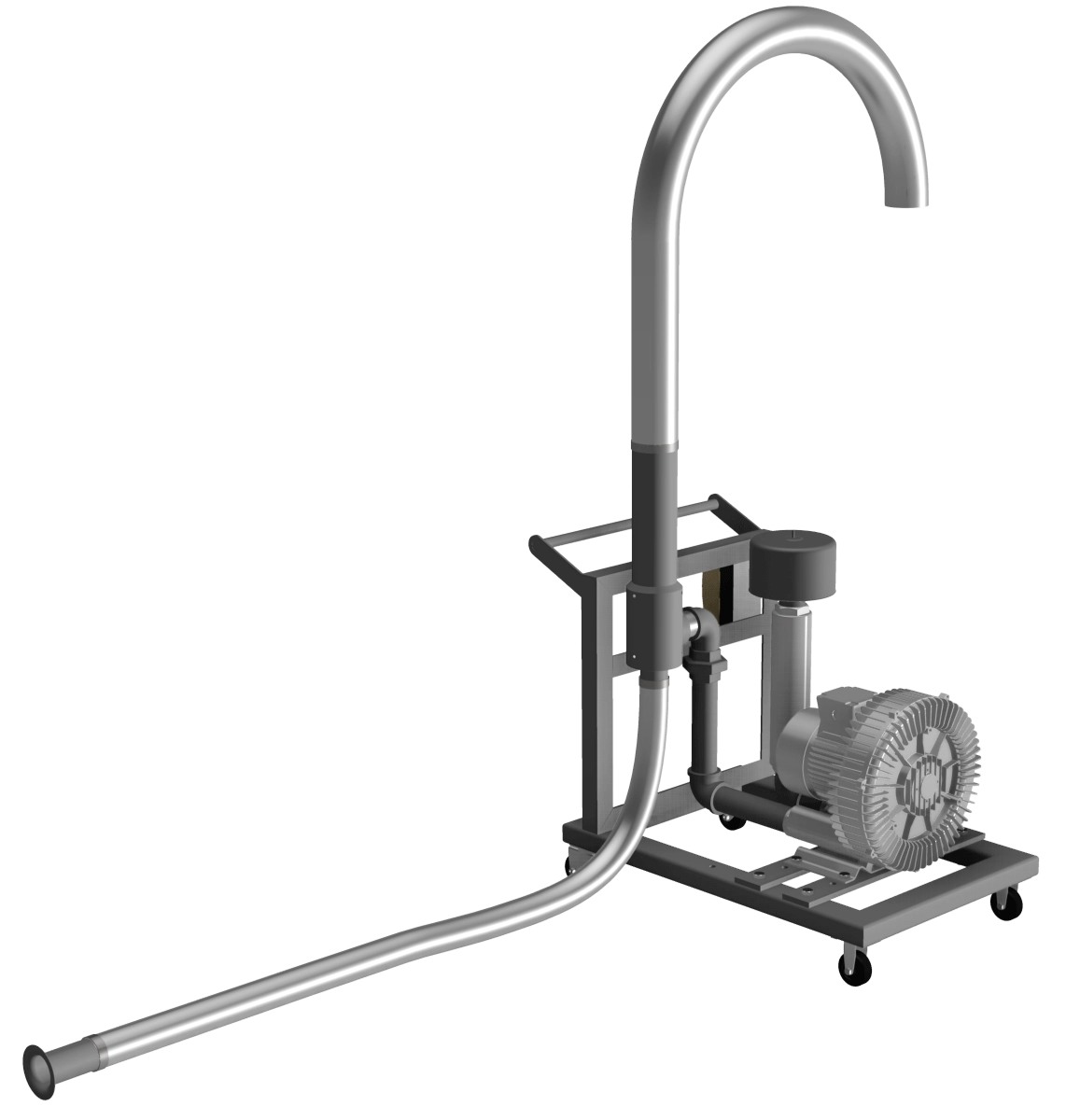

FOX Runner Portable Waste Removal Systems

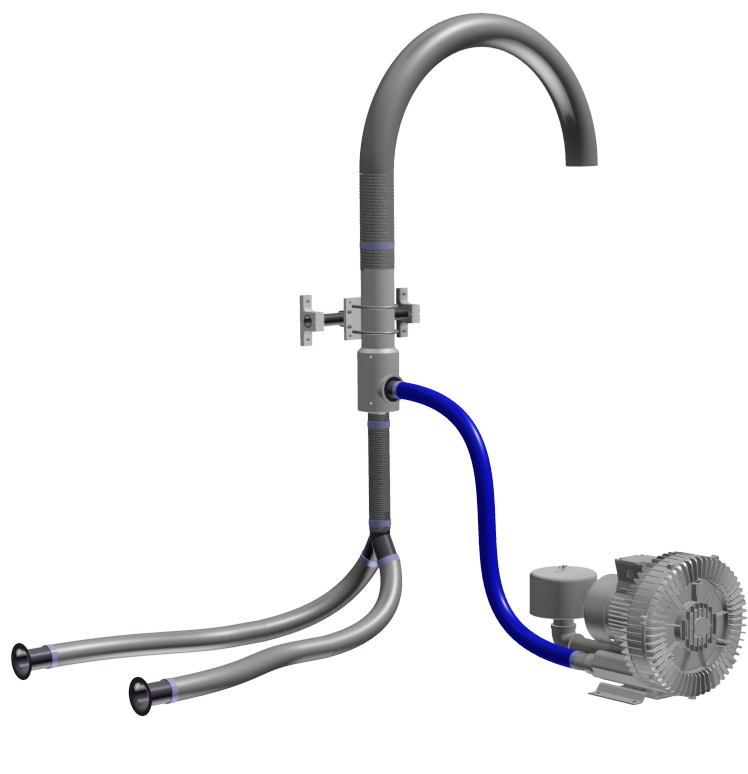

One Pick-Up & Two Pick-Up FOX Runner Portable Systems

The One Pick-Up and Two Pick-Up FOX Runner Portable Systems are fully portable waste removal solutions built on the proven FOX TrimAway technology. Each system features an exclusive venturi design and a high-efficiency regenerative blower that deliver powerful suction and discharge airflow for reliable trim and matrix conveying.

The One Pick-Up model is ideal for single-source waste removal, while the Two Pick-Up version includes dual intake nozzles and a Y-connector to handle two trim lines or machines at once.

Ready to run in minutes, the One Pick-Up and Two Pick-Up FOX Runner Portable Systems offer quiet, energy-efficient, and low-maintenance performance wherever portable trim removal is needed. Efficiently remove paper, film, foil, textile and non-woven trims. Great for picking up and removing pieces, as well as chopped, granulated, and palletized materials.

Features:

Available options:

One Pick-Up FOX Runner Portable System |

|

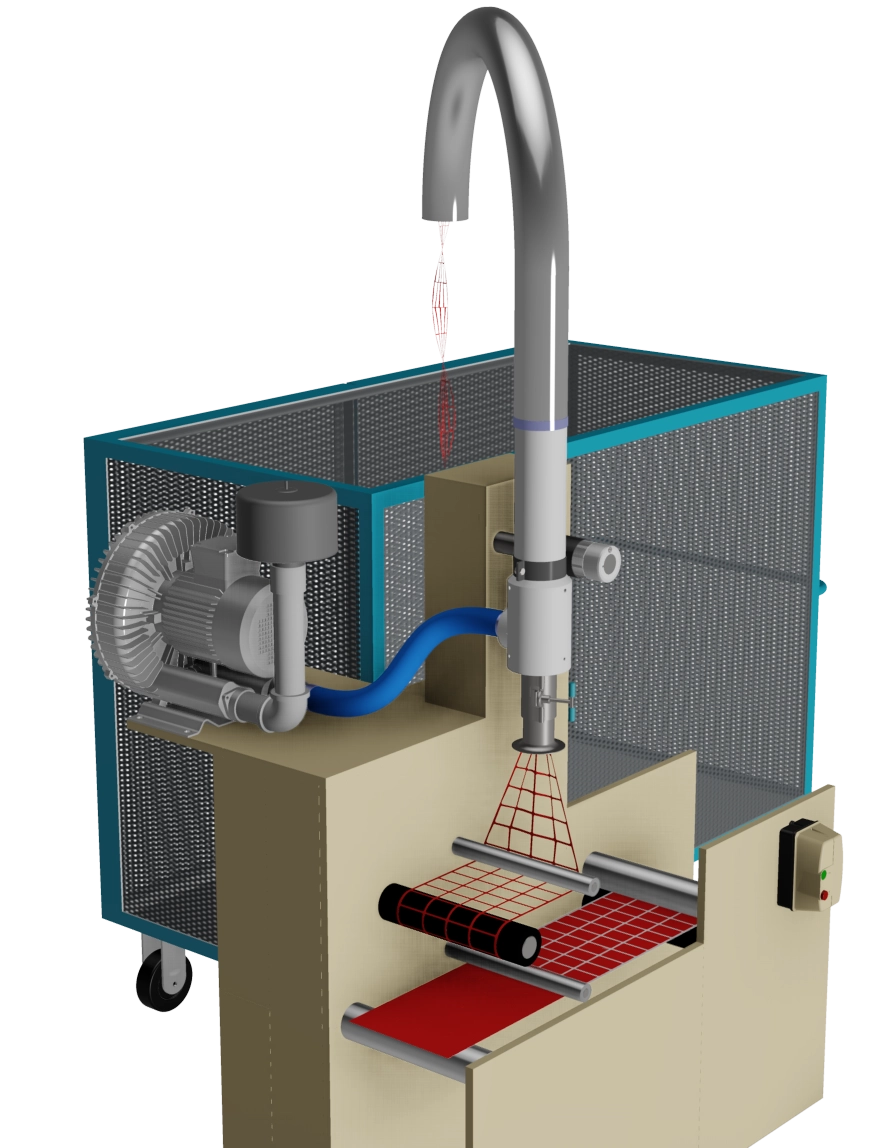

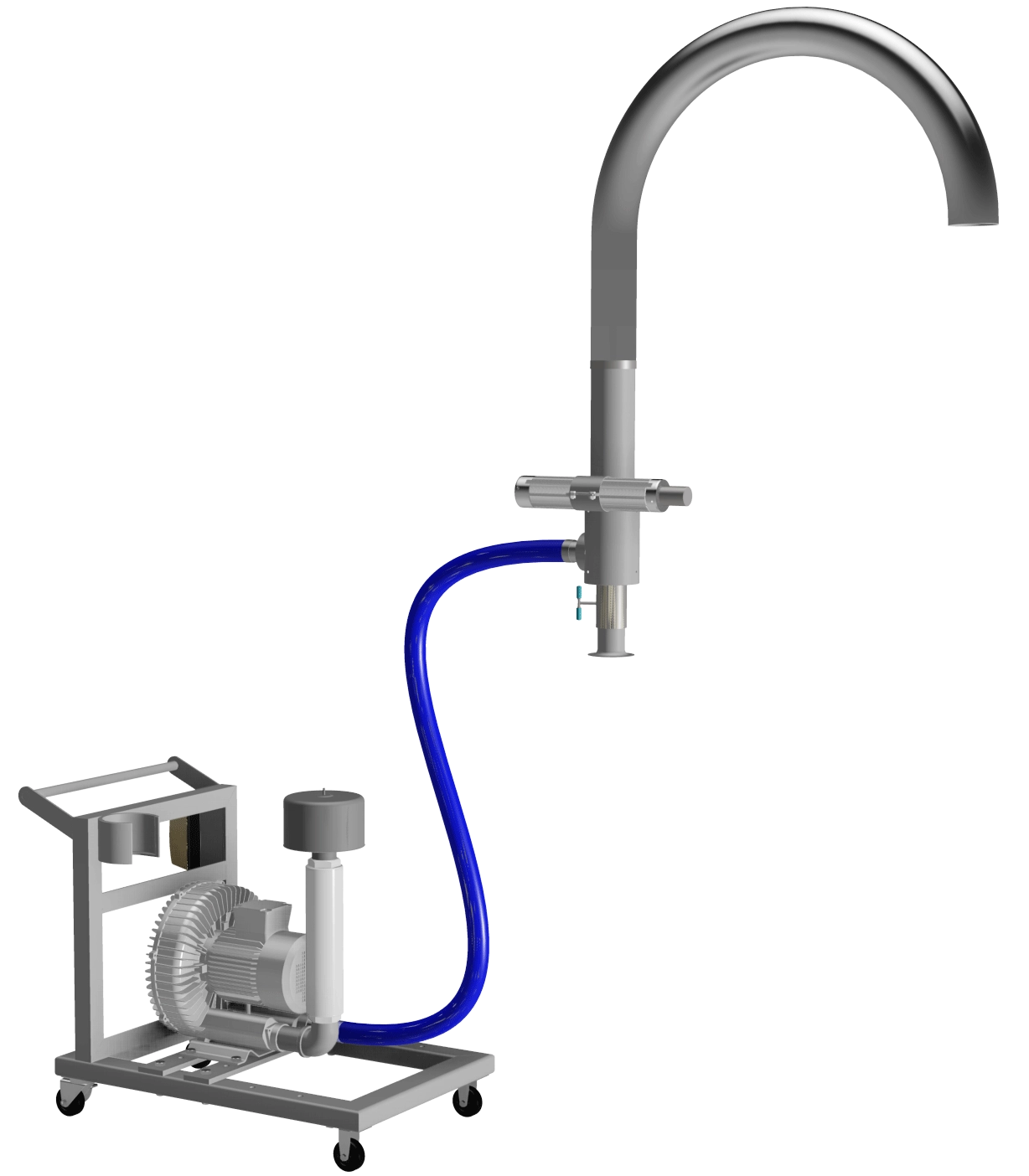

Matrix Removal FOX Runner Portable System

The Matrix Removal FOX Runner Portable System, built on the FOX TrimAway technology, is a portable system designed for fast, efficient matrix waste removal. With it’s quick set up, simply roll it into place and connect power, the Matrix Removal FOX Runner™ Portable System is ready to use in minutes. Using the exclusive FOX venturi and a quiet, energy-efficient regenerative blower, it generates strong suction and pressure airflow to collect and convey matrix waste directly from the press. Optional PTFE-lined components handle matrix with exposed adhesive without the use of oils or other contaminates. Capable of handling matrix up to 22 inches wide and high running speeds, this system offers reliable, low-maintenance performance for removing paper, board, film, foil and matrix. Optional components also available to customize the system to fit your production’s needs.

Features:

Available options:

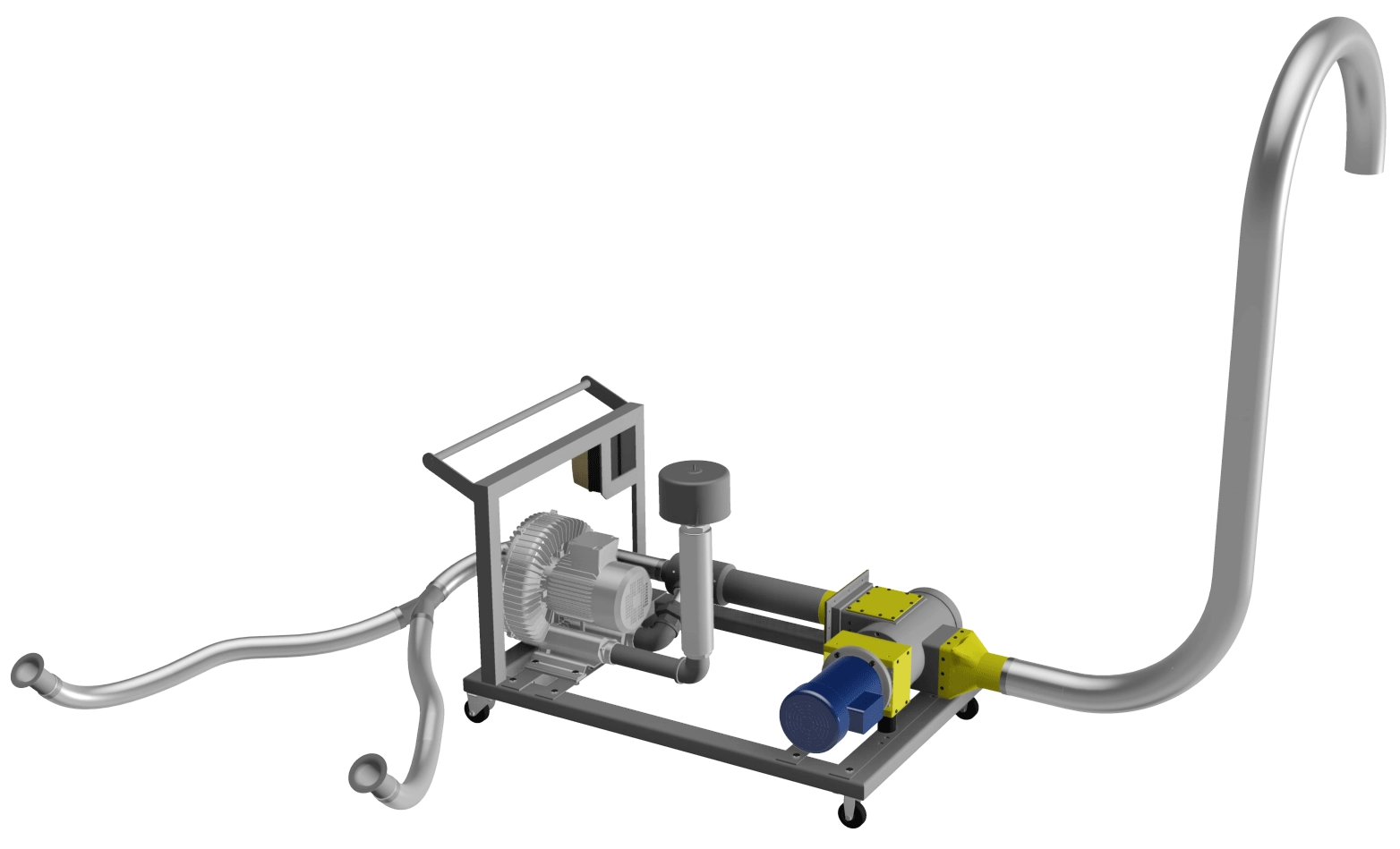

FOX Runner Portable System with Chopper

Built on the FOX TrimAway System, this portable option has an integrated Trim-AX chopper. The Trim-AX chopper is for cutting continuous trim or matrix in manageable segments prior to conveying therefor making cleanup and waste handling easier. Processing of one or two lines (up to 6” wide each) is possible. Operation can handle speeds up to 6,000 fpm and discharge material over 100 feet (in favorable setups). The FOX Runner Portable System with Chopper uses the exclusive venturi found in all FOX TrimAway systems for a powerful, quiet, and energy efficient.

Features:

Available options:

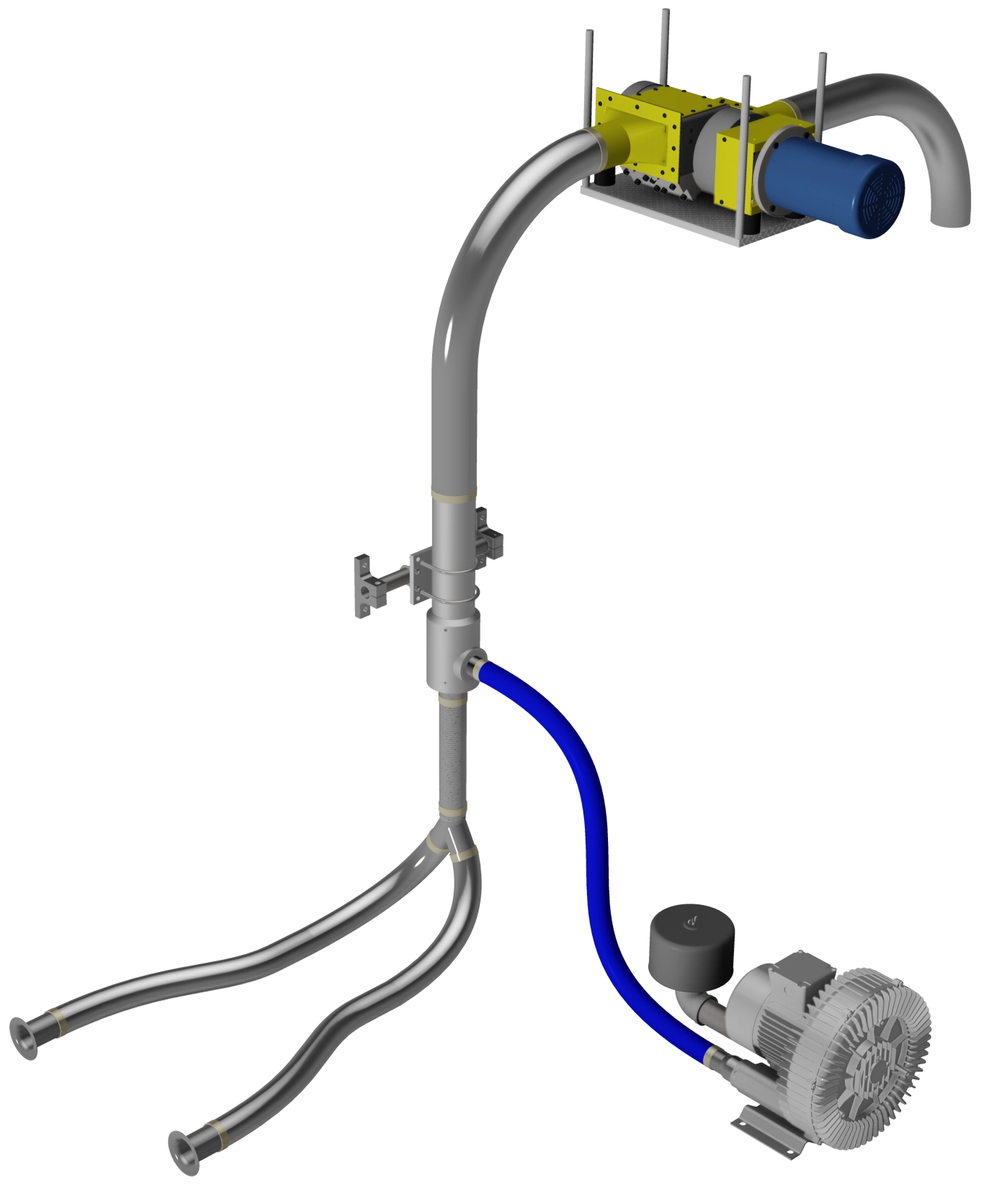

FOX TrimAway Trim Conveying System with Chopper

The FOX TrimAway Trim Conveying System with Chopper is built on the FOX TrimAway system with the addition of the Trim-AX chopper. The Trim-AX chopper is a heavy-duty chopper designed to chop extremely light to very thick and heavy materials. With durable all-steel construction and precision engineering and CNC machining, the Trim-AX is designed to operate with minimal vibration, noise, and maintenance. Seamlessly integrating with FOX TrimAway and FOX Runner systems, or even existing setups, the Trim-AX improves conveying distance, enhances efficiency, and reduces the volume of waste in collection bins.

Features:

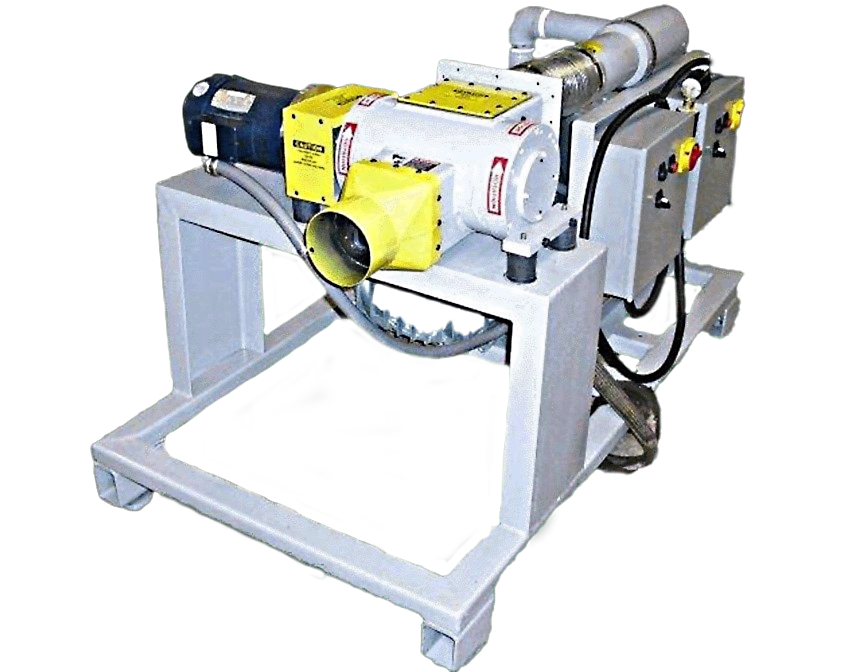

FOX Combo Portable Trim Removal and Chopper System

The FOX Combo Portable Trim Removal and Chopper System combine the venturi-based FOX TrimAway trim removal technology with a Trim-AX dual-blade chopper. Both the blower and the chopper are mounted to a movable frame. Trim material up to 6” wide and operating speeds up to 3,000 fpm can be handled by the system while the Trim-AX is capable of 3,450 cuts per minute. Optional features are available to customize the system to fit your production’s exact needs.

Features: