PRODUCT FINDER

Which products are best for you?

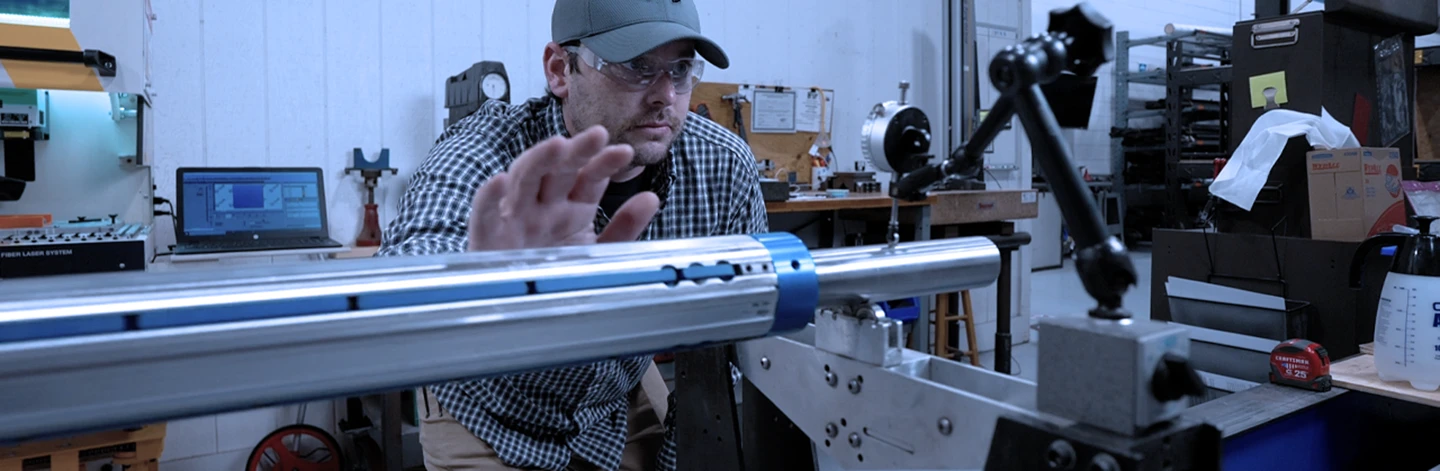

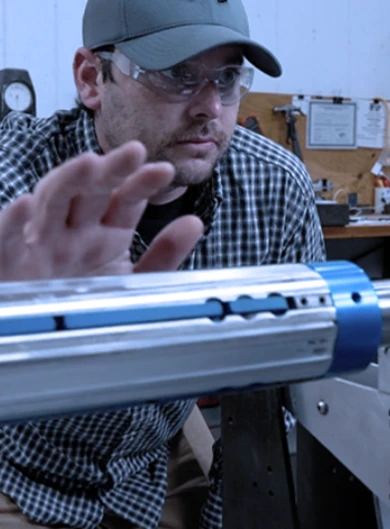

Metal Expanding Lug Shafts

The DG-2000 pneumatic metal expanding lug shaft features the heavy duty construction required for use in the converting industry along with critical ergonomics to ensure worker safety and efficiency.

Manufactured with the user in mind, Double E Group’s metal expanding lug shafts utilize our proprietary lightweight bladder technology and quick-change journal systems to limit costly converting line downtime.

The DG-2000 pneumatic metal expanding lug shaft features the heavy duty construction required for use in the converting industry along with critical ergonomics to ensure worker safety and efficiency.

Manufactured with the user in mind, Double E Group’s metal expanding lug shafts utilize our proprietary lightweight bladder technology and quick-change journal systems to limit costly converting line downtime.

Engineered specifically for the converting industry, ShaftSafe® is the first real time air pressure monitoring system for Double E Group and Convertech air shafts and bladder chucks

ShaftSafe® Features:

Backed by more than 50 years of experience, all products manufactured by Double E Group including our metal expanding lug shafts are covered by a one-year warranty and will be free from defects in workmanship and materials for a period of twelve months from the date of original shipment to the original buyer.

DG-2000 Metal Air Shafts

Competing air shaft bladders are made with a common form of neoprene rubber which requires frequent replacement due to stretching and abrasion.

Double E Group air shaft lugs are available with a “diamond-grip” surface in steel, aluminum, or hard rubber, and have been field-proven to provide the maximum gripping performance possible.

Easy-maintenance journal connection - secured with flathead screws, a close tolerance fit, and deep insertion. Competing air shafts (roll shafts) often use a tapered press fit, which requires a hydraulic press and heat to remove the journals. Bladder replacement on these shafts can take hours while the bladder of a Dyna–Grip air shaft can be changed in just a few minutes.

DLB-2000 Carbon Fiber Air Shafts

Replace heavy steel core shafts without sacrificing strength or stiffness. Carbon fiber core shafts are typically half the weight of their steel counterparts.

For more specific information about the Double E Group carbon fiber air shafts, please click here.

Which products are best for you?

Back to Top