PRODUCT FINDER

Which products are best for you?

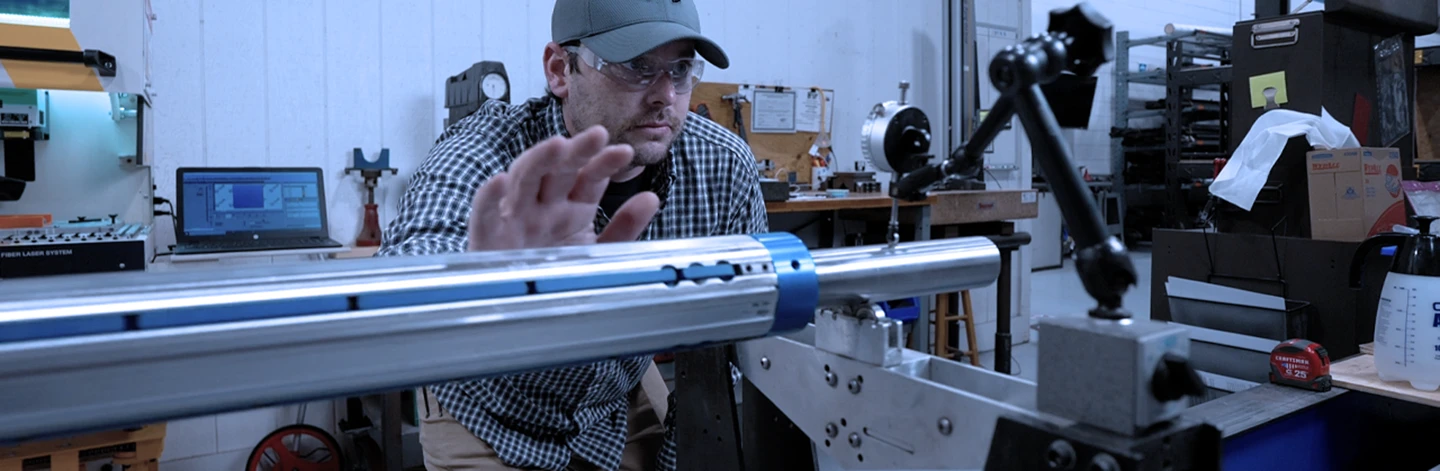

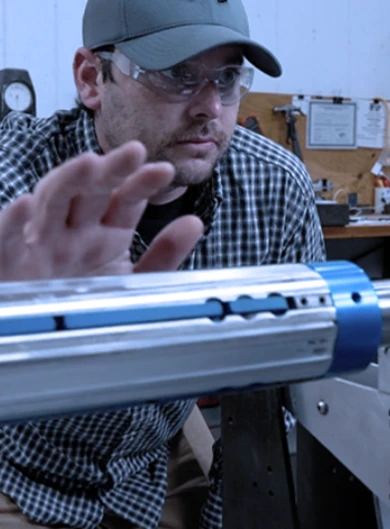

Digital Slitter Positioning System

Increased accuracy and decreased downtime in shear, crush, or razor slitting applications

Intuitive digital positioning system facilitates the placement of slitter groups.

Important benefits of the digital slitter system

Digital slitter system - components and options

“Critical components of the Lynx system are the display, the sensor bar, and individual push buttons. The buttons allow positioning of holders relative to a set zero point and/or to each other (if two are engaged at the same time).

Linking pins are available to connect top and bottom groups together. This capability yields similar functionality to a fully automatic positioning system at a fraction of the cost.

Which products are best for you?

Back to Top